Equipment

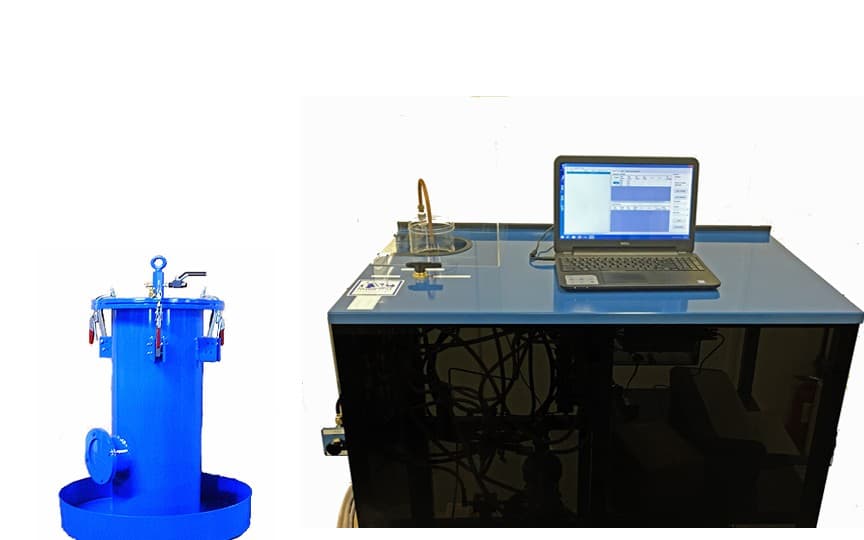

#507-hp-14s-m: Software Driven Water Jacket Test System, With 14″d X 40″t Water Jacket

Utilities required to operate

- 8CFM @ 100psi of pre-regulated shop air

- Inlet water supply

- Consistent and stable air temperature

- Overhead I-beam with hoist and trolley

- 12′ Ceiling height

- 115V – 1phase – 60Hz electrical

(converter available for 220V-50Hz)

$20,500.00 | SKU: 507-HP-14S-M

Automated Hydrostatic Water Jacket Cylinder Test System

Meets U.S. DOT requirements

Test range of 2000 – 10,000 psi in automated mode

Test range of 2000 – 10,000 psi in manual mode

Software operates test functions and records test results

Sleek – low profile modern cabinet design

Automated Features

- User friendly software program reduces human error

- Software calculates all expansion values and pass/fail criteria based on expansion values

- Pass fail criteria can be defined on % expansion or REE value ( for carbon fiber cylinders )

- Pressure hold time can be set up to 24 hours ( in seconds )

- Operator types in cylinder info and test criteria – clicks test button – test is then run and recorded

- Daily verification automated calibrated cylinder run

- DOT warning for improper verification procedure

- Detailed history screen allows date and field sort

- Records easily printable or exported as .csv files

- User defined templates are easily added and controlled

- Allows loading of cylinder information in batches or singularly

- System can be operated in manual mode for ease of troubleshooting

Air operated test pump

- Stainless steel water section

- Soft seated check valves

- Contaminant free design – for O2 cylinder testing

- 14″ diameter x 40″ tall

- Accepts cylinders to 12″ diameter x 34″ tall

- Low pressure safety relief port

- High and low pressure air bleed valves

- Manual operated lid closure

- Floor mounted – no need for pit

- Used for periodic re calibration of electronic sensors

- Class 3A – 1/4% accuracy

- 8.5″ diameter

- 11,000psi x 20psi increments

- For full test range

- Test adapter and expansion chart included

- 700g Net expansion value x 0.1g increments

- Calibration weights included

- IBM compatible Laptop

- Ink-jet printer

Safety relief

Written instructional manual

Operational training seminar at Hydro-Test in Stow, Massachusetts

- For up to 4 people

- Valid for 90 days after purchase of test system